Core Concept: Consolidate Demand, Decentralize Delivery

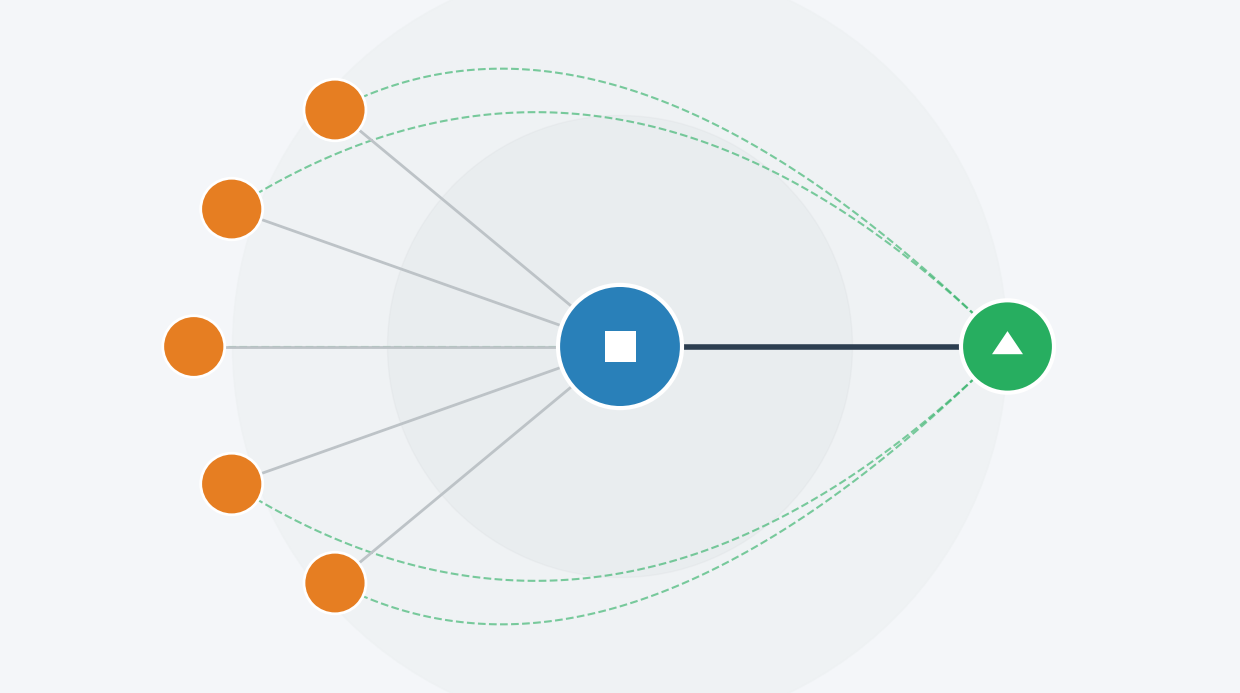

Centralized purchasing separates the transactional flow (ordering) from the physical flow (delivery):

- Transactional Flow: Local purchase requisitions are consolidated into a single Purchase Order (PO) by a central purchaser. This PO is issued to the supplier as a unified order.

- Physical Flow: The supplier delivers goods directly to the demand site, eliminating internal inventory transactions and reducing logistical complexity.

Key Benefit: No internal inventory transactions are required between the demand site and the ordering site, as receipt and arrival registration occur at the demand site.

Strategic Configuration and Prerequisites

To implement centralized purchasing effectively, enforce the following data consistency rules:

1. Purchase Part Standardization

All sites must use identical:

- Part Numbers: Ensure the same part number is used across all locations.

- Unit of Measure (UoM): Standardize the purchase UoM and conversion factors to inventory UoM.

- Catalog Alignment: The central purchasing site’s catalog must include all parts from demand sites.

Failure to standardize: Leads to order errors, delayed deliveries, and increased operational costs.

2. Site Basic Data Setup

Configure site-level rules to define interactions between central and local entities:

- Validity Periods: Define time intervals for default purchasing sites.

- Pricing Logic: Choose whether prices are fetched from the Purchasing Site (PO Header) or Demand Site (PO Line).

- Strategic Note: Using «Demand Site» pricing simplifies part administration by limiting basic data setup to the demand site.

Operational Workflow

From Requisition to Order

The transition from local requisition to central order can be automated or manual:

- Automatic Detection: The «Central Order» option is enabled automatically if the demand site has valid centralized basic data.

- Manual Selection: Buyers can manually select the central order option and specify the site and part pricing method.

- Consolidation: Buyers can add lines to existing POs, converting normal POs to centralized POs.

Receipt and Arrival

Receipt and arrival registration are handled entirely by demand sites:

- No central action is required for part arrivals.

- Inventory transactions are recorded locally as usual.

- For direct customer deliveries, the end customer’s address is saved on the PO line, and the process is managed by the demand site.

Risk Mitigation and Data Integration

Data Consistency Risks

Inconsistent part data across sites can disrupt centralized purchasing. Mitigate risks by:

- Conducting a pre-implementation audit of part numbers, UoM, and catalogs.

- Using Data Mesh and OData projections for real-time data synchronization.

Testing Scenarios

Before go-live, test the following scenarios:

- Multi-site orders to a single supplier.

- Direct deliveries to end customers.

- Manual override of automated central order detection.

Frequently Asked Questions (FAQ)

- How does the system determine the price for a centralized order?

- A centralized order retrieves price-related information from either the Purchasing Site (PO Header) or the Demand Site (PO Line), based on configuration.

- Are internal inventory transactions required between the central site and local sites?

- No. Receipt and arrival registration at the demand site eliminate the need for internal inventory transactions.

- What happens if centralized basic data is missing during requisition conversion?

- The «Central Order» option will not enable automatically. However, buyers can manually select it and specify part pricing and site details.

- Must part numbers be identical across all sites?

- Yes. Parts must have the same number, UoM, and conversion factors across all sites to ensure seamless processing.

- How can Data Mesh improve centralized purchasing?

- Data Mesh enables real-time data synchronization across decentralized locations, ensuring consistency and reducing errors in multi-site procurement.

Implementation Checklist

Use this checklist to ensure a successful centralized purchasing implementation:

- Audit part numbers, UoM, and catalogs for consistency across all sites.

- Configure validity periods and pricing logic for each site.

- Test automated and manual central order processes.

- Simulate direct deliveries to end customers.

- Integrate Data Mesh for real-time data synchronization (if applicable).

- Train procurement teams on new workflows and error handling.

Key Performance Indicators (KPIs)

Measure the success of your centralized purchasing implementation with these KPIs:

- Reduction in the number of purchase orders by X%.

- Decrease in order processing time by Y days.

- Cost savings from bulk purchasing and improved supplier terms.

- Reduction in order errors and delivery delays.

Centralized Purchasing FAQ

How does the system determine the price for a centralized order?

A centralized order retrieves price-related information from either the Purchasing Site (PO Header) or the Demand Site (PO Line). This depends entirely on your specific configuration preferences for pricing logic.

Are internal inventory transactions required between the central site and local sites?

No. One of the key benefits of this model is that receipt and arrival registration occur directly at the demand site, effectively eliminating the need for complex internal inventory transactions.

What happens if centralized basic data is missing during requisition conversion?

The system is designed for safety; the «Central Order» option will not enable automatically if data is missing. However, buyers can intervene by manually selecting the option and specifying the necessary part pricing and site details.

Must part numbers be identical across all sites?

Yes, this is a strict prerequisite. For seamless processing, parts must share the same Part Number, Unit of Measure (UoM), and conversion factors across all participating sites.

How can Data Mesh improve centralized purchasing?

Data Mesh architecture facilitates real-time data synchronization across decentralized locations. This ensures consistency (e.g., matching part numbers) and significantly reduces errors inherent in multi-site procurement strategies.